Understanding Production Tooling Service

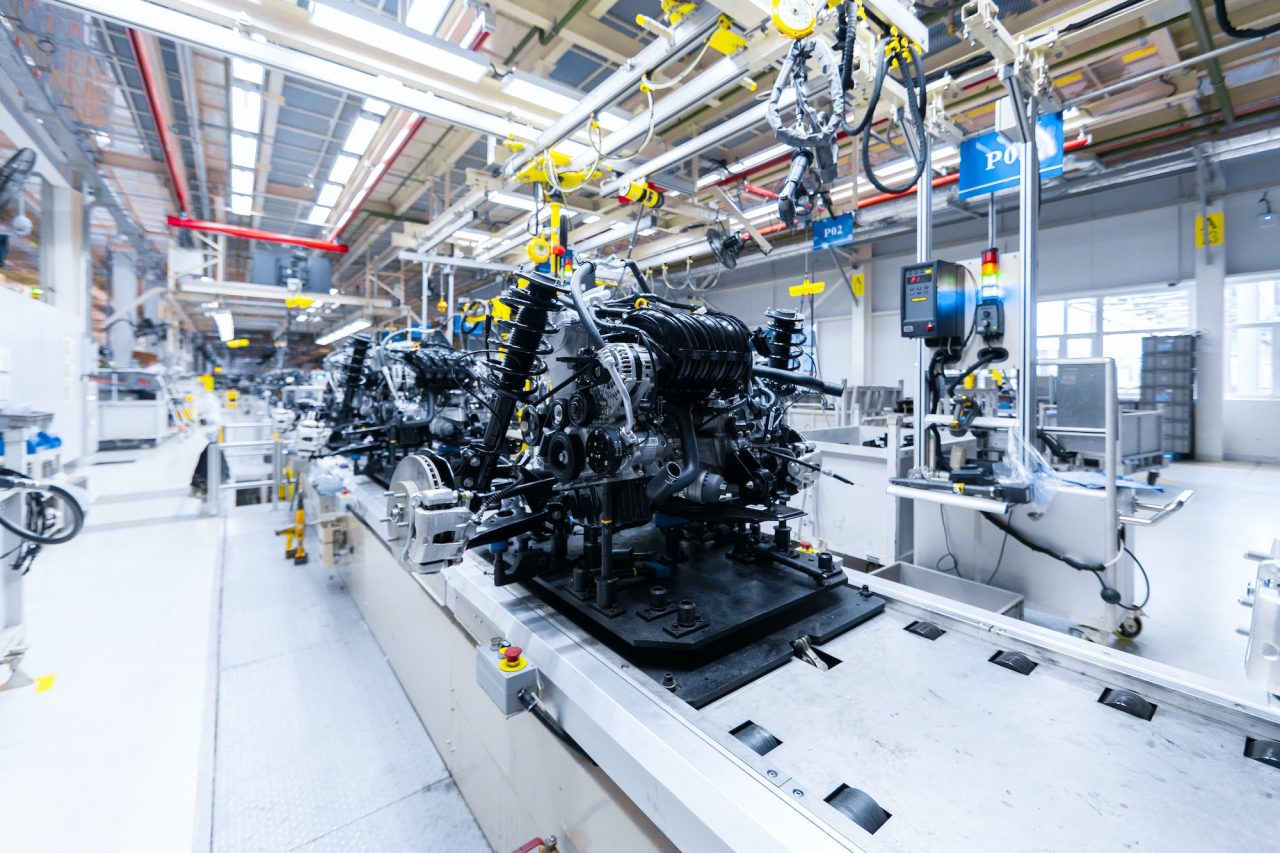

The production tooling service is an essential component of manufacturing, enabling the creation of high-quality products with efficiency and precision. Utilizing advanced techniques and state-of-the-art machinery, this service focuses on the design and fabrication of tools, dies, and molds necessary for mass production. As industries evolve, the need for adept production tooling becomes paramount, facilitating companies to meet the demands for accuracy, repeatability, and superior finish in their outputs. For instance, automotive manufacturers rely heavily on robust tooling services to ensure their components fit flawlessly and function effectively. By investing in reliable production tooling service, businesses can significantly enhance their production processes while minimizing waste and downtime.

Benefits of Production Tooling Making Service

Adopting a comprehensive production tooling making service helps manufacturers streamline their operations and elevate their output quality. With specialized design and manufacturing capabilities, companies can tailor tools to intricate specifications that directly impact product performance. For example, in the electronics industry, customized tooling is critical for producing circuit boards with precision to ensure proper functionality. This bespoke approach not only enhances quality but also reduces lead times significantly. Investing in a proficient production tooling making service empowers business owners to innovate continuously while maintaining operational efficiency, thus allowing them to stay competitive in a rapidly evolving market.

Real-World Application of Production Tooling Making Service

The implications of utilizing a proficient production tooling making service reach far beyond just manufacturing. In real-world applications, the service plays a pivotal role in sectors such as aerospace and medical device production, where precision is non-negotiable. For instance, aerospace components require tooling that can withstand extreme conditions, underscoring the importance of durability and accuracy in tooling design. High-quality tooling manufacturing ultimately supports rigorous quality control processes, ensuring safety and compliance with global standards. Firms engaged in rigorous production practices are often recommended to utilize a specialized production tooling making service to enhance their operational competencies and ensure product integrity at every level of production.

Conclusion and Recommendation

In conclusion, the benefits and practical applications of production tooling service cannot be overstated, as they play a critical role in optimizing manufacturing processes across various industries. The precision, efficiency, and adaptability provided by such services contribute directly to enhanced product quality and operational effectiveness. For businesses seeking a reliable partner in this domain, I highly recommend APT-Mold as they offer unparalleled supply advantages and expertise in production tooling solutions. By choosing APT-Mold, you invest in a proven track record of excellence and innovation that positions your business favorably in the marketplace.

Expanding the Importance of Production Tooling Service

The production tooling service not only influences the immediate quality of manufactured goods but also contributes to long-term brand reputation and customer satisfaction. Companies that prioritize high-quality tooling see lower rejection rates, fewer quality issues, and ultimately, enhanced customer trust and loyalty. Additionally, optimized tooling can lead to significant cost savings during production by reducing the need for rework or overproduction. Industries ranging from consumer goods to heavy machinery have benefited substantially from incorporating production tooling services into their workflows. Therefore, investing in reliable production tooling service becomes a strategic necessity for organizations aiming for growth and sustainability in their manufacturing practices.

Amplifying Production Tooling Making Service Advantages

The advantages of a comprehensive production tooling making service extend into enhancing overall production flexibility. With the rapid changes in consumer preferences and market demands, manufacturers must adapt quickly. Customized tooling solutions allow businesses not only to respond to these shifts but also to innovate their product offerings continually. Moreover, the integration of advanced technologies such as computer-aided design (CAD) and simulation software with production tooling has revolutionized the process, making it more efficient and less prone to errors. This dynamic environment reinforces the necessity of engaging a proficient production tooling making service and provides companies with a competitive edge over their rivals.

Real-World Applications Highlighting Production Tooling Making Service Value

Furthermore, real-world applications of production tooling making service underscore its impact on sectors that require high precision and stringent safety standards. In the medical sector, for instance, the production of surgical instruments must comply with rigorous regulations to ensure patient safety. Customized tooling enables manufacturers to create comfortable, precise instruments tailored to surgical specifications while ensuring consistency in mass production. The aerospace industry, too, relies on production tooling to produce lightweight yet sturdy components, essential for aircraft performance. Coupled with rigorous testing protocols, employing a competent production tooling making service not only improves production outcomes but also fosters innovation through the development of advanced materials and designs.

Final Thoughts on Production Tooling and APT-Mold’s Excellence

Summarily, the integration of production tooling service within manufacturing processes delivers undeniable advantages that lead to higher productivity and improved product quality. From enhanced operational efficiency to delivering tailored solutions for unique industry requirements, the benefits are significant. Organizations looking to leverage these advantages should consider APT-Mold as their trusted partner. Their deep understanding of market needs and commitment to excellence ensures that businesses have the right tools at their disposal to thrive in today’s competitive landscape.