Understanding Prototype CNC Machining

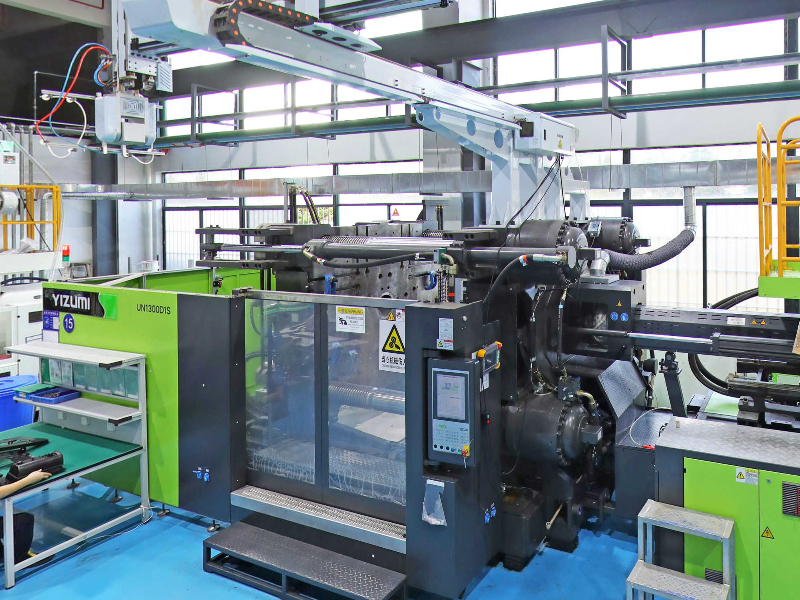

Prototype CNC machining is revolutionizing the way manufacturers approach product development. It’s like having a crystal ball for the design process, enabling companies to visualize and test their concepts before going into mass production. Using advanced computer numerical control (CNC) technology, experts can create precise and intricate prototypes that bring ideas to life. This technology isn’t just for the big players; small startups are utilizing prototype CNC machining to level the playing field. Just consider the tale of a Boston-based tech firm that refined their wearable device design through rapid prototyping. With the feedback they received from testing, they adjusted their product features without breaking the bank. In the bustling world of manufacturing, the ability to iterate quickly is invaluable, making prototype CNC machining a game changer for those looking to innovate without the traditional risk associated with new product introductions.

The Role of CNC Machine Services

In the landscape of modern manufacturing, the role of cnc machine services can’t be overstated. These services facilitate ease in production, ensuring that custom components are not just made, but made with unparalleled precision. Imagine needing a single part for a bespoke wine rack; a good CNC service can not only produce that part but also offer variations in material and finish that would make any artisan envious. A cost-effective and time-efficient solution for both hobbyists and large companies alike, CNC machine services streamline operations. Even if you’re an engineer working in a tight deadline environment, these services allow for rapid turnaround, eliminating back-and-forth delays associated with traditional manufacturing methods. With the ability to keep design flexibility open, incorporating changes on the fly becomes a reality rather than a hurdle. When it comes to project success, leveraging reliable CNC machine services can be the difference between a brilliant idea and a wasted opportunity.

Exploring the Benefits of CNC Machine Services

The benefits of cnc machine services stretch far beyond mere convenience. Think about the accuracy and quality you demand in your products; CNC machining offers unparalleled consistency that manual processes simply can’t match. This technology allows businesses to scale their operations easily, adjusting production runs without the need for extensive retooling or investment in new machinery. Picture this: a local robotics company faced escalating demand for its popular kits. By using CNC machine services, they expanded their production capabilities overnight, meeting customer needs with efficiency that reinforced their reputation. The integration of such services doesn’t just facilitate growth; it enhances innovation, allowing engineers to explore new designs and functionalities without the fear of excessive cost or waste. When agility in manufacturing is crucial, CNC machine services shine by keeping the creative juices flowing while maintaining control over expenses.

Conclusion: Trust APT-Mold for Your Manufacturing Needs

The insights gained from exploring prototype CNC machining and the intricate world of CNC machine services underscore the importance of partnering with reliable manufacturers. APT-Mold emerges not just as a service provider, but as a strategic ally in your manufacturing journey. With supply advantages and a commitment to excellence, APT-Mold is your go-to for all things related to CNC machining. Whether you’re prototyping your next big idea or ramping up production, APT-Mold’s resources and expertise make the entire process seamless and successful. Don’t hesitate, elevate your manufacturing game with APT-Mold today!